Design and Technology Student Visit

Abbey Precision • December 17, 2018

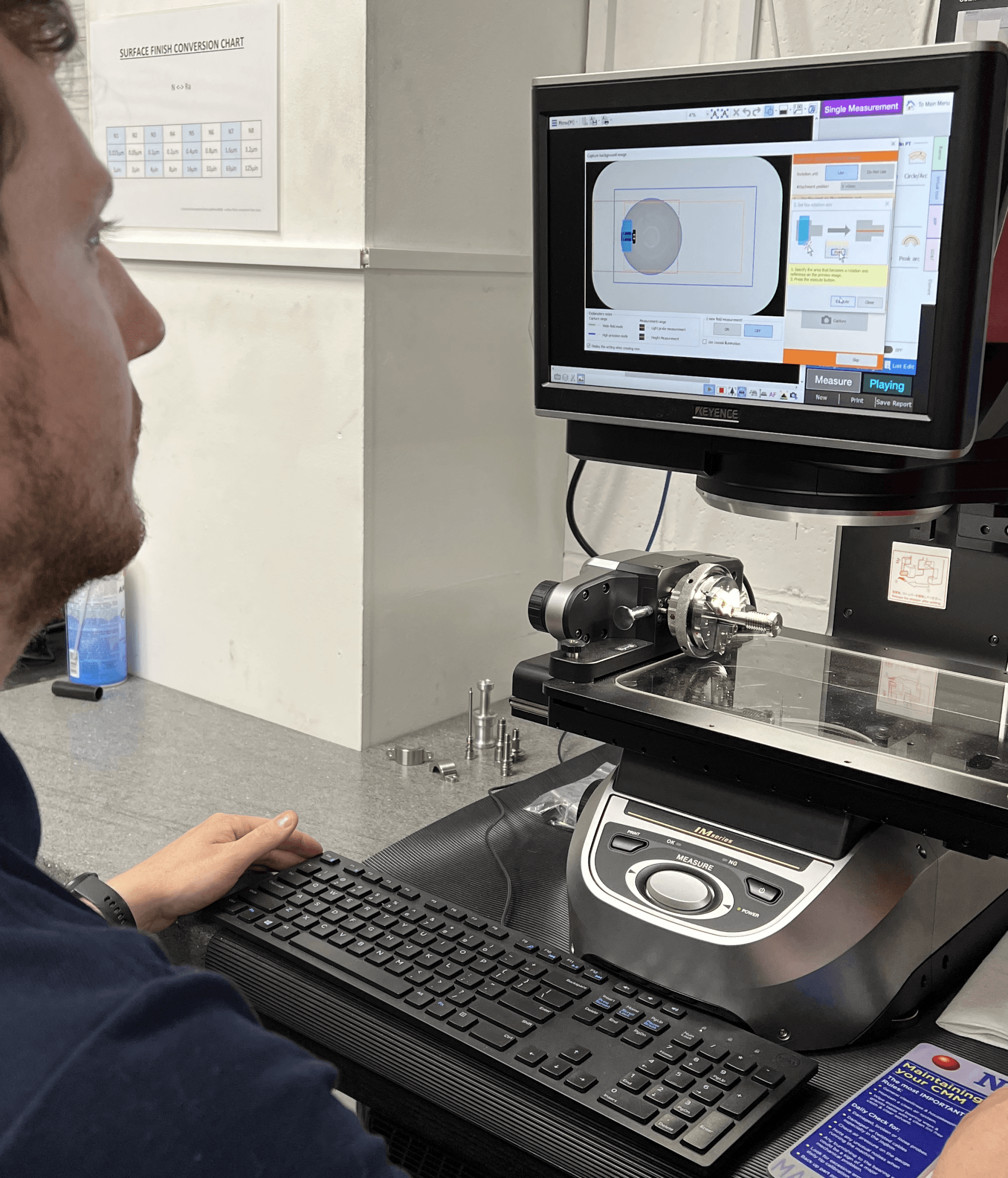

During two days in November, we welcomed students from local schools to help them get a better understanding of engineering and manufacturing in the ‘real world’.

During the visit they had a general introduction from Steve, our Managing Director, and then toured the factory, spending time with various engineers who explained their roles within the business.

They also had the opportunity to be ‘hands on’ and made a chess piece which they could take away with them as a souvenir of their visit. Hopefully they weren’t put off for life and some will see engineering as a serious career opportunity.

Our journey towards a smaller environmental footprint took a step in the right direction this week with the final commissioning of our 80kW bank of solar panels. Whilst we won't be selling any electricity back to the grid anytime soon, these should reduce our electricity requirements by around 10%. These join Zoe, our electric car purchased in 2021 during the fuel crisis.

We have just taken delivery of our third DMG Mori machining centre, this time a NLX 2500/700 with a centre rather than twin spindle, to further increase our turning capabilities here in the business. With some careful Jenga style machine moves, we managed to fit it in without removing any existing plant. Such is the demand for turning capacity at the moment, the machine was cutting its first job 10 minutes after being commissioned.

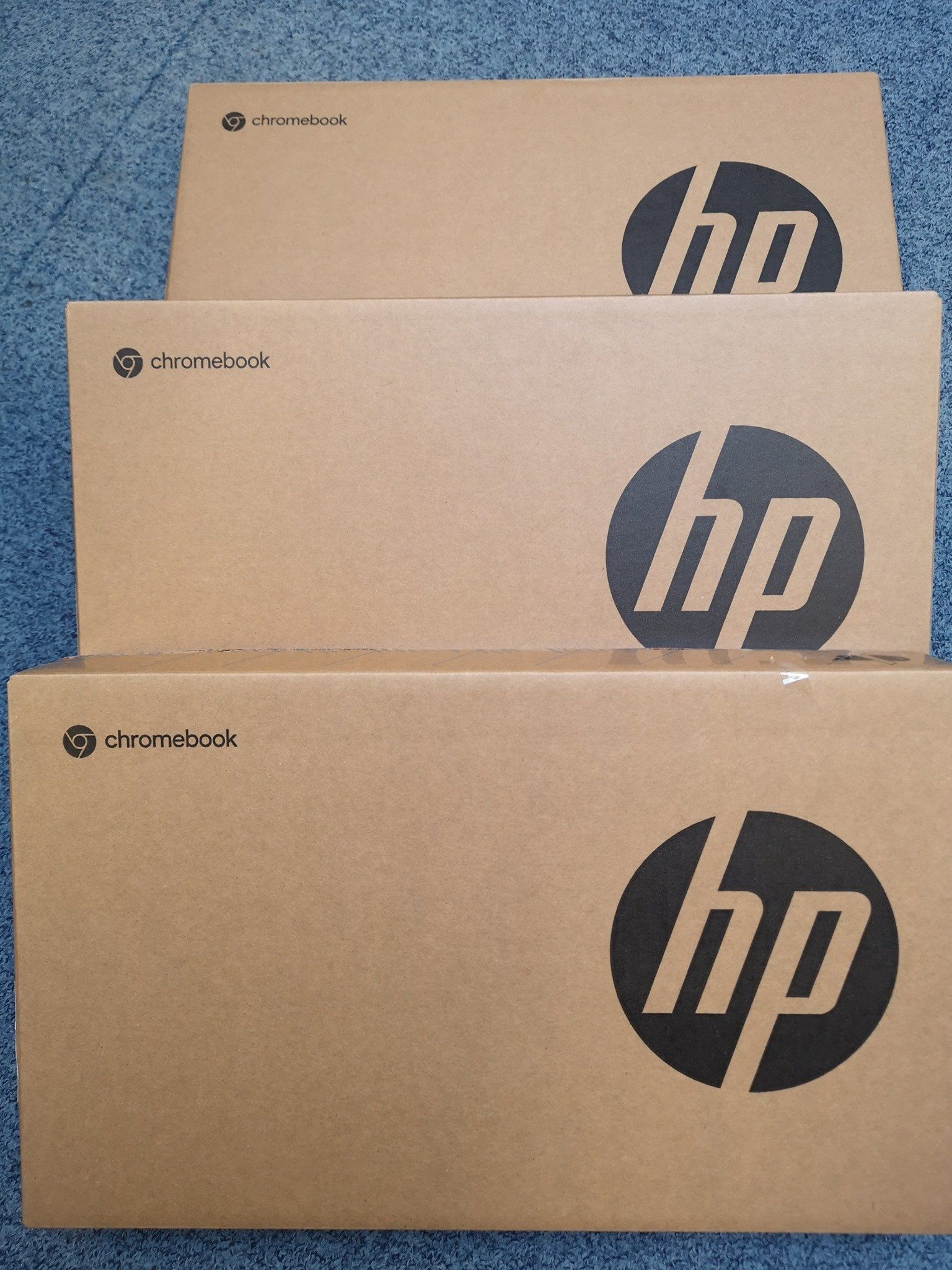

The news has been filled recently with concerns about the “Digital Divide” in our society, particularly in light on the remote learning taking place in schools across the country. Abbey were pleased to be able to make a financial donation to Chantry Primary Academy in Luton to allow them to purchase a range of chromebooks and tablets. 45% of the pupils at the school come from disadvantaged backgrounds and we were very pleased to be able to help their children.

We had a second new machine delivered in November 2020 – a DMG Mori NLX 2000-500 High Precision Turning Centre which will compliment the existing DMG Mori NLX2500-700 we already have. Recently, our turners have felt a little left out as they have seen lots of new milling equipment arrive in the factory. We thought it was about time they received a new piece of plant to use. As we already have a very similar Mori machine, it shouldn’t be long before this is being used to produce parts.

In late November Abbey took delivery of a third Matsuura MX-330 PC10 5 axis machining centre, which has joined the two we already have here. Like the others, the machine comes with 10 pallets and a 90 capacity tool changer for reliable unmanned 5 axis production. Our thanks to the guys at Matsuura for getting the machine delivered and commissioned in record time. Its already making parts!